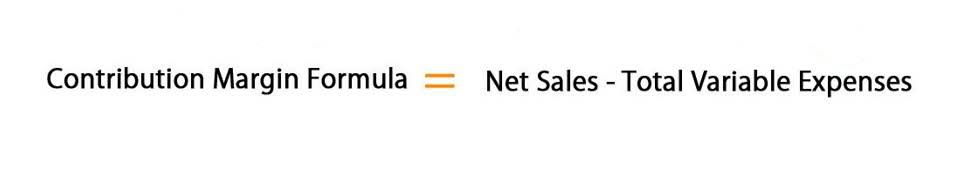

This practice holds great importance as it allows for a thorough understanding of cost differentials and enables us to assess the accuracy of our initial estimates. However, it’s equally important to consider the impact on machine maintenance costs. As you produce more, your machinery’s wear and tear intensify, requiring increased maintenance contribution margin and potentially additional repairs. Irrespective of the scale of your enterprise, understanding this measurement empowers you to enhance efficiency and increase profitability. By obtaining a transparent breakdown of expenses, you can make well-informed choices, pinpoint areas for enhancement, and streamline your workflows. CNC milling offers several advantages, including high precision, repeatability, and the ability to produce complex and intricate parts.

Determine the Quantity of Materials Used

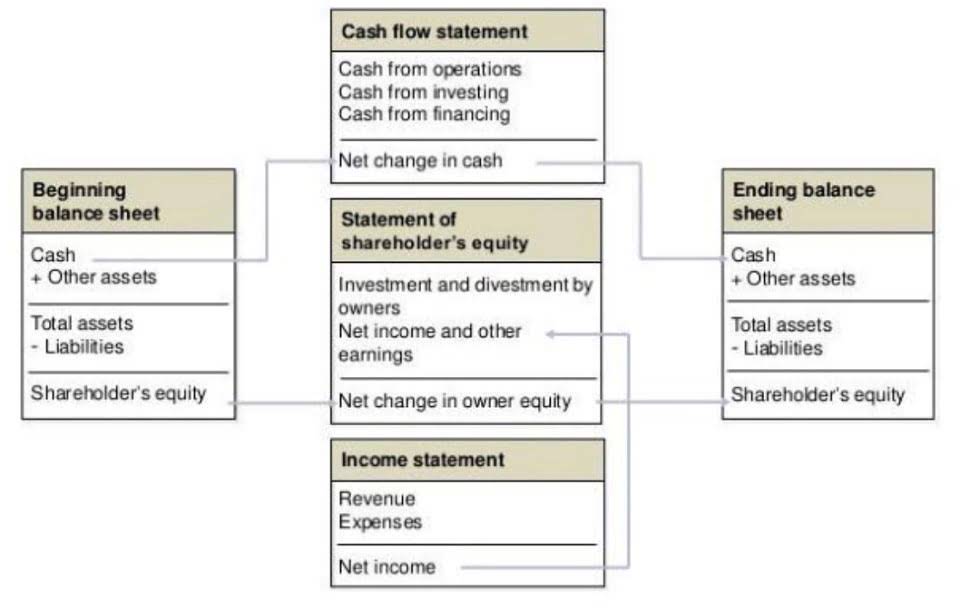

Manufacturing overhead expenses include various indirect costs necessary to support the production process. These expenses may cover machinery maintenance, utilities, facility rent, and other essential overhead components. It’s easy to confuse total manufacturing cost with the cost of goods sold (COGS), but they are different concepts. Total Manufacturing Cost refers to all the costs involved in creating your product, including materials, labor, and overhead. COGS, on the other hand, is the cost of the inventory that was actually sold during a specific period.

- This practice holds great importance as it allows for a thorough understanding of cost differentials and enables us to assess the accuracy of our initial estimates.

- Total Manufacturing Cost refers to all the costs involved in creating your product, including materials, labor, and overhead.

- The direct material cost should never be calculated by multiplying the number of final products with the material quantities from their BOMs.

- To calculate total manufacturing costs, you must first sum up all the direct materials used in production.

- You can adapt to evolving needs and maximize profitability by continuously reviewing and refining your allocation techniques.

- Amidst these endeavors, it is crucial to prioritize a thorough understanding of total manufacturing cost.

- By investing in employee training and development, companies can foster a culture of efficiency where workers are empowered to identify and eliminate inefficiencies.

Improved Cost Control and Expense Management

- Effective cost management systems help control expenses, improve efficiency, and boost profitability.

- With a laser focus on delivering exceptional products while maintaining profitability, you’re on the path to sustainable success in the competitive manufacturing landscape.

- Valuing the diverse skill sets, strengths and perspectives of our workforce, we foster a collaborative environment that actively engages all team members and promotes trust and integrity.

- When considering the total manufacturing cost, it’s important to factor in how machinery shipping services impact overall expenses.

- However, water could also be used as an indirect material to wash the bottles or equipment.

Remember, understanding and managing your total manufacturing cost is the key to maximizing profitability. Scaling your production is exciting, but it’s vital to recognize that not all production costs scale simultaneously. As your output increases, it’s crucial to consider the dynamics of specific cost components. Assuming the direct labor cost for producing the dining table set amounts to $300, you can attribute this value to the expertise and efforts invested by your labor.

- Imagine that a production manager, John, in a furniture manufacturing company analyzes the TMC every quarter to determine the total manufacturing cost variance from the standard or estimated figures.

- These expenses constitute indirect costs, at least from the perspective of the manufacturing process, and are allocated as overheads.

- Understanding these nuances allows us to effectively plan and allocate resources to support our growth and profitability goals.

- It’s useful to note that the same raw material might also be used as both direct and indirect material pools.

- These are the tangible inputs that become an integral part of the product and can be easily traced back to it.

- Discover budget-friendly platforms, AI tools, and lean strategies to launch and grow your e-commerce business without breaking the bank.

- Imagine a toy manufacturer calculating the total direct manufacturing cost for a specific toy, including the cost of plastic, paint, and the wages of the workers assembling it.

Example: Calculating Total Manufacturing Cost for “HomeStyle Furnishings”

Some companies may even decide to include costs related to training the production staff in direct labor costs. While quite basic on paper, gathering precise information on all these constituents can be a challenge Bakery Accounting in real life. Since the total manufacturing cost is an essential metric for understanding the productivity and profitability of a business, it really pays to get it right the first time. The concept of total manufacturing cost has been a cornerstone in industrial and manufacturing economics for centuries.

- To determine the total cost of manufacturing for a specific period, businesses must first compile the expenses incurred from direct materials, direct labor, and manufacturing overhead.

- By deeply understanding your total manufacturing cost, you can make informed decisions regarding pricing strategies and effective cost management.

- Regularly updating and reviewing costs will further enhance your overall cost efficiency.

- Factory manufacturing cost provides insights into the specific expenses related to production, excluding other costs such as selling and administrative expenses.

- Regularly reassess your allocation methods to ensure they remain accurate and fair.

- He currently serves on the Boards of Tri-W Group (formerly W.W. Williams), Nationwide Energy Partners and Armada Power LLC.

It is computed by dividing the total manufacturing cost in a given period by the total number of units of a particular commodity produced in that period. If the company produces 5000 bags quarterly, determine the total manufacturing cost per unit. For a computer manufacturer, this would include the cost of components, assembly total manufacturing cost formula labor, and overhead costs like electricity for the production facility. By closely tracking these variations, we can make well-informed decisions, identify areas for improvement, and optimize our overall financial performance. This analysis allows us to identify potential underestimation or overestimation of production costs and make necessary adjustments. While allocating overhead costs may present challenges, it is possible to overcome them and maximize profitability with the right approach.

Meet Our Leadership: The Driving Force Behind Total Manufacturing

Discover budget-friendly platforms, AI tools, and lean strategies to launch and grow your e-commerce business without breaking the bank. Jim Baich is the founder and owner of MAD Capital, a holding company of private commercial real estate and mid-market operating companies. Prior to MAD, Jim was Chief Operating Officer at both Advanced Drainage Systems and IGS Energy, both billion-dollar companies.